One of the decisions that business owners face when starting a plastic molding business, or expanding an existing one, is whether they should buy new or used injection molding machines for their facility.

If you too are encountering such a predicament and can’t seem to decide whether to shop new or buy used, then you’re in luck. This post discusses some of the hidden benefits that convince most plastic molders to opt for used plastic machinery for their facility. And if your competitors are benefitting from something, surely you can too.

Why Investing in Used Injection Molding Machine and Equipment Could be A Good Idea

When buying something, a person’s instinct is to go for a brand new version of that product. However, when buying plastic molding machinery and equipment, most business owners are often constrained by their budget due to the enormous capital cost of new machinery.

In these cases, many molders turn to second-hand machinery, which, contrary to popular belief, can be a profitable route to follow.

Let’s look at some of the reasons why investing in used plastic machinery could prove to be valuable for your business.

More Affordable

Stating the obvious, but probably the most significant reason most plastic molders opt to go the used machinery route when shopping for their plastic molding equipment is the price tag that used machines sport.

While new machines may demand thousands of dollars upfront, the prices of previously-owned molding machines are significantly lower. Many used machines can have almost all of the same features and productivity as that of new machines at a fraction of the price.

Because used machines are more affordable, they do not demand a hefty upfront investment and business owners can buy right out of their pocket, without having to go for financing.

Therefore, investing in used injection molding equipment can prove to be a good deal, getting you great productivity, optimized cycle times, and an efficient machine without you having to exhaust your savings or drain your profit on interest and fees that accompany financing.

Immediate Deployment

People who have bought new machinery know how long they have to wait to get their order shipped.

New machines have a longer estimated delivery time, and that’s excluding the not-so-uncommon delays. Used machines, on the other hand, are assembled and refurbished, ready to go within weeks or even days of placing your order.

In the production and manufacturing arena, time is money. The sooner your equipment arrives at your facility the quicker it can start paying for itself and generating a return on your investment.

This leads to the next point:

Used Machines Generate Quicker Return on Investment (ROI)

Used machines return your investment sooner, assuming that you have purchased a high-quality machine from a reputable seller.

One of the reasons why used injection molding machines generate a quicker ROI is the smaller initial investment.

Secondly, as discussed above, used machines are deployed earlier and hence start production soon after they are acquired. And early production of plastic parts means early profit. So used injection molding machines begin to pay for themselves sooner than the new machines.

Better Resale Value

You may know how the value of tangible assets depreciates rapidly when they are new and that the rate of depreciation drops after a few years.

Used machines are usually past their initial depreciation period, which means their price will not drop too steeply after you have bought them. Moreover, previously-owned machines from top brands, like used Nissei injection molding machines, hold their value for a long time. Therefore, they have a better resale value if you choose to sell your machine and invest your capital elsewhere.

Well-Kept Maintenance Record

Used machines have most likely been in service in a well-reputed facility where machines and equipment are maintained regularly.

When you buy used plastic injection molding machines, sometimes you can get their maintenance records which would be valuable for you as it would provide all of their maintenance information without you having to go through trial and error to develop a good maintenance routine.

For example, the previous owner may have had a routine of when the machine needs maintenance. Going through the maintenance records, you can easily adopt the routine of the previous owner, understand when certain consumable parts of the machine need to be replaced, and practice preventive maintenance.

No Guess Work

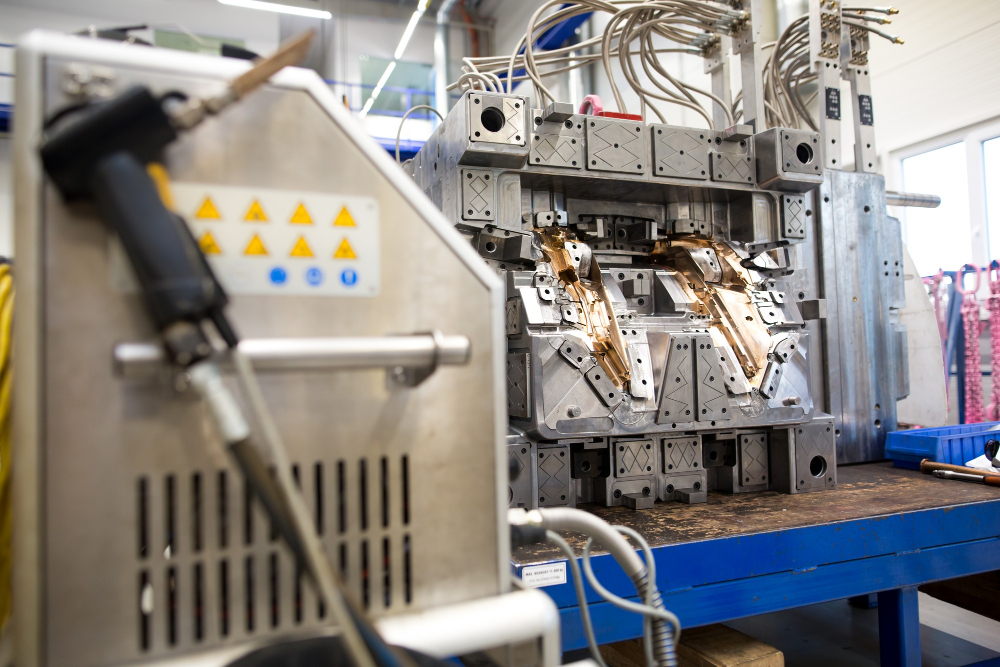

Sellers who deal in used plastic molding equipment often repair them before putting them up for sale. Having inspected the machines thoroughly and fixing them, these people have a deep insight into their actual features.

When buying new, you will most likely be told about the machine’s ideal uptime and reliability, that is, how many similar parts the machine can make consistently. However, the actual uptime and reliability differ from the ideal values, which you will have to figure out yourself.

If buying used equipment, you can ask your seller about the machine’s actual production capacity and its true cycle time, that is, the time to make one part (or parts in case of multi-cavity machines). Used equipment sellers will most likely have this kind of information and other details because they would have run tests on the machine before making it available for purchase.

You can benefit from all this information, eliminating the guesswork and the need to spend precious production time figuring out these critical process variables.

High Quality

Second-hand in the plastic molding world does not necessarily equate to low quality. When shopping for plastic machinery, you can get your hands on very high-quality equipment, like used Nissei injection molding machines, at a fraction of the price of their brand new versions. The only requirement is that you search for a trustworthy seller.

Such sellers procure machines from promising suppliers or partners who have upgraded their equipment, repair them, replace damaged parts, and then sell them to their customers. They thrive on good customer relationships so the quality is there, and you need not worry about getting scammed.

About PPS

Premier Plastic Systems has been serving the plastics sector since 1999. Being the manufacturer’s representative for new injection molding equipment and with an impeccable list of used Nissei injection molding machines and refurbished plastic machinery and equipment from other well-known brands, they help plastic molders get their business off the ground or expand beyond bounds by supplying premium quality plastic machinery at an affordable price.